Minimal 3DP Projects, Ideas, and Links

This section is my attempt to document my projects, ideas, and other informational links/references.

This is the multi-page printable view of this section. Click here to print.

Minimal 3DP Projects, Ideas, and Links

This section is my attempt to document my projects, ideas, and other informational links/references.

As I am putting together this site, I thought it was important to try to document my projects.

For the most part I will try to document each project as I put it together. This will include references, tools, printers, settings, and anything else I need to remember.

This site is built with Hugo. I am utilizing the Docsy theme by Google. As a side note, I have found it easy to use and I like the documentation.

3D Printers

Ender 3 S1 Plus

Ender 3 S1 Plus landing page.

Ender 3 S1 Plus with the default Creality Board

# !Ender-3 S1 Plus

# printer_size: 300x300x300

# version: 3.6

# This file contains pin mappings for the stock 2021 Creality Ender 3

# S1 & S1 Pro. To use this config, check the STM32 Chip on the

# Mainboard, during "make menuconfig" select accordingly either the

# STM32F103 with "28KiB bootloader" or the STM32F401 with

# "64KiB bootloader" and serial (on USART1 PA10/PA9) for both.

# For a direct serial connection, in "make menuconfig" select

# "Enable extra low-level configuration options" and Serial

# (on USART2 PA3/PA2), which is on the 10 pin IDC cable used

# Flash this firmware by copying "out/klipper.bin" to a SD card and

# turning on the printer with the card inserted. The filename

# must be changed to "firmware.bin"

# With STM32F401, you might need to put "firmware.bin" in a

# folder on the SD card called "STM32F4_UPDATE" in order to flash.

# See docs/Config_Reference.md for a description of parameters.

###fluidd set

[include cx_printer.cfg]

[display_status]

[pause_resume]

[gcode_macro PAUSE]

description: Pause the actual running print

rename_existing: PAUSE_BASE

# change this if you need more or less extrusion

variable_extrude: 1.0

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

##### set park positon for x and y #####

# default is your max posion from your printer.cfg

{% set x_park = printer.toolhead.axis_maximum.x|float - 5.0 %}

{% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

##### calculate save lift position #####

{% set max_z = printer.toolhead.axis_maximum.z|float %}

{% set act_z = printer.toolhead.position.z|float %}

{% if act_z < (max_z - 2.0) %}

{% set z_safe = 2.0 %}

{% else %}

{% set z_safe = max_z - act_z %}

{% endif %}

##### end of definitions #####

PAUSE_BASE

G91

{% if printer.extruder.can_extrude|lower == 'true' %}

G1 E-{E} F2100

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

{% if "xyz" in printer.toolhead.homed_axes %}

G1 Z{z_safe} F900

G90

G1 X{x_park} Y{y_park} F6000

{% else %}

{action_respond_info("Printer not homed")}

{% endif %}

[gcode_macro RESUME]

description: Resume the actual running print

rename_existing: RESUME_BASE

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

#### get VELOCITY parameter if specified ####

{% if 'VELOCITY' in params|upper %}

{% set get_params = ('VELOCITY=' + params.VELOCITY) %}

{%else %}

{% set get_params = "" %}

{% endif %}

##### end of definitions #####

{% if printer.extruder.can_extrude|lower == 'true' %}

G91

G1 E{E} F2100

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

RESUME_BASE {get_params}

[gcode_macro CANCEL_PRINT]

description: Cancel the actual running print

rename_existing: CANCEL_PRINT_BASE

gcode:

TURN_OFF_HEATERS

{% if "xyz" in printer.toolhead.homed_axes %}

G91

G1 Z4.5 F300

G90

{% else %}

{action_respond_info("Printer not homed")}

{% endif %}

G28 X Y

{% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

G1 Y{y_park} F2000

M84

CANCEL_PRINT_BASE

[stepper_x]

step_pin: PC2

dir_pin: PB9

enable_pin: !PC3

rotation_distance: 40

microsteps: 16

endstop_pin: !PA5

position_min: -5

position_endstop: -5

position_max: 305

homing_speed: 80

[stepper_y]

step_pin: PB8

dir_pin: PB7

enable_pin: !PC3

rotation_distance: 40

microsteps: 16

endstop_pin: !PA6

position_min: -2

position_endstop: -2

position_max: 305

homing_speed: 80

[stepper_z]

step_pin: PB6

dir_pin: !PB5

enable_pin: !PC3

rotation_distance: 8

microsteps: 16

endstop_pin: probe:z_virtual_endstop #enable to use bltouch

#endstop_pin: !PA15 #disable to use bltouch

#position_endstop: -0.1

position_min: -10

position_max: 305

homing_speed: 4

second_homing_speed: 1

homing_retract_dist: 2.0

[extruder]

max_extrude_only_distance: 1000.0

step_pin: PB4

dir_pin: PB3

enable_pin: !PC3

rotation_distance: 7.74

microsteps: 16

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PA1

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC5

#control: pid

# tuned for stock hardware with 200 degree Celsius target

#pid_Kp: 23.904

#pid_Ki: 1.476

#pid_Kd: 96.810

min_temp: 0

max_temp: 265

[idle_timeout]

timeout: 172800

[heater_bed]

heater_pin: PA7

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC4

#control: pid

# tuned for stock hardware with 50 degree Celsius target

#pid_Kp: 74.000

#pid_Ki: 1.965

#pid_Kd: 696.525

min_temp: 0

max_temp: 130

[verify_heater extruder]

check_gain_time: 200

hysteresis: 5

[fan]

pin: PA0

kick_start_time: 0.5

#set heater fan runnig with temperature over 60;

[heater_fan my_nozzle_fan]

pin: PC0

max_power: 0.8

shutdown_speed : 0

heater:extruder

heater_temp : 60

fan_speed : 1.0

[mcu]

serial: /dev/serial/by-id/usb_serial_1

restart_method: command

# [mcu rpi]

# serial: /tmp/klipper_host_mcu

# [adxl345]

# cs_pin: rpi:None

# spi_speed: 2000000

# spi_bus: spidev2.0

# [resonance_tester]

# accel_chip: adxl345

# accel_per_hz: 70

# probe_points:

# 150,150,10

[input_shaper]

shaper_type_x = mzv

shaper_freq_x = 59.2

shaper_type_y = mzv

shaper_freq_y = 30.0

[filament_switch_sensor filament_sensor]

pause_on_runout: true

switch_pin: ^!PC15

[bltouch]

sensor_pin: ^PC14 #signal check port ^stand for pull up

control_pin: PC13 #singal control prot

x_offset: -30.0

y_offset: -40.0

#z_offset: 0 #z off_set configuration

stow_on_each_sample = false #high speed for bltoch,

speed: 3.0

samples: 2

samples_result: median

sample_retract_dist: 6.0

samples_tolerance: 0.01

samples_tolerance_retries: 3

[safe_z_home]

home_xy_position:185,195

speed: 200

z_hop: 10

z_hop_speed: 10

[bed_mesh]

speed: 150

mesh_min: 25,30 #need to handle head distance with bl_touch

mesh_max: 273,250 #max probe range

probe_count: 5,5

fade_start: 1

fade_end: 10

algorithm: bicubic

[bed_screws]

screw1: 25, 33

screw2: 262, 33

screw3: 262, 272

screw4: 25, 272

[gcode_arcs]

#resolution: 1.0

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 4000

max_z_velocity: 10

max_z_accel: 1000

square_corner_velocity: 5.0

[exclude_object]

[include timelapse.cfg]

[include cx_gmcro.cfg]

Artillery Sidewinder X1 (SWX1)

SWX1 landing page.

SWX1 with a BTT SKR 2

[include shell_command.cfg]

[include fluidd.cfg]

[include mainsail.cfg]

# This file contains common pin mappings for the BigTreeTech SKR 2.

# To use this config, the firmware should be compiled for the

# STM32F407 with a "32KiB bootloader".

# In newer versions of this board shipped in late 2021 the STM32F429

# is used, if this is the case compile for this with a "32KiB bootloader"

# You will need to check the chip on your board to identify which you have.

#

# The "make flash" command does not work on the SKR 2. Instead,

# after running "make", copy the generated "out/klipper.bin" file to a

# file named "firmware.bin" on an SD card and then restart the SKR 2

# with that SD card.

# See docs/Config_Reference.md for a description of parameters.

# Note: The initial revision of this board has a flaw that can cause

# damage to itself and other boards. Be sure to verify the board is

# not impacted by this flaw before using it.

[stepper_x]

step_pin: PE2

dir_pin: !PE1

enable_pin: !PE3

microsteps: 16

rotation_distance: 40

endstop_pin: ^!PC1

position_endstop: 0

position_max: 300

homing_speed: 100

[tmc2209 stepper_x]

uart_pin: PE0

run_current: 0.800

diag_pin:

[stepper_y]

step_pin: PD5

dir_pin: !PD4

enable_pin: !PD6

microsteps: 16

rotation_distance: 40

endstop_pin: ^!PC3

position_endstop: 0

position_max: 300

homing_speed: 100

[tmc2209 stepper_y]

uart_pin: PD3

run_current: 0.800

diag_pin:

[stepper_z]

step_pin: PA15

dir_pin: PA8

enable_pin: !PD1

microsteps: 16

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop

position_max: 400

homing_speed: 20

second_homing_speed: 1

[tmc2209 stepper_z]

uart_pin: PD0

run_current: 0.800

diag_pin:

[stepper_z1]

step_pin: PD11

dir_pin: PD10

enable_pin: !PD13

microsteps: 16

rotation_distance: 8

[tmc2209 stepper_z1]

uart_pin: PD12

run_current: 0.800

diag_pin:

[extruder]

step_pin: PD15

dir_pin: PD14

enable_pin: !PC7

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PB3

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PA2

#control: pid

#pid_Kp: 22.2

#pid_Ki: 1.08

#pid_Kd: 114

min_temp: 0

max_temp: 250

[tmc2209 extruder]

uart_pin: PC6

run_current: 0.600

diag_pin:

[heater_bed]

heater_pin: PD7

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PA1

#control: pid

min_temp: 0

max_temp: 130

#pid_kp: 42.365

#pid_ki: 0.545

#pid_kd: 822.940

[fan]

pin: PB7

[heater_fan fan1]

pin: PB6

#[heater_fan fan2]

#pin: PB5

# Due to BTT implementing a Marlin-specific safety feature,

# "anti-reversal stepper protection", this pin needs pulling

# high to pass power to stepper drivers and most FETs

[output_pin motor_power]

pin: PC13

value: 1

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f429xx_200044001450304738323420-if00

[printer]

kinematics: cartesian

max_velocity: 250

max_accel: 3000

max_z_velocity: 50

max_z_accel: 400

square_corner_velocity: 5.0

[bltouch]

## If these change, adjust coords in [z_tilt], [safe_z_home]

sensor_pin: ^PE4

control_pin: PE5

x_offset: 29

y_offset: -34

z_offset: 10

samples: 3

samples_result:average

probe_with_touch_mode: true

stow_on_each_sample: false

[safe_z_home]

home_xy_position: 122,183

speed: 150

z_hop: 10 # Move up 10mm

z_hop_speed: 5

[bed_screws]

screw1: 55,55

screw1_name: front left

screw2: 255,55

screw2_name: front right

screw3: 255,255

screw3_name: back right

screw4: 55,255

screw4_name: back left

speed: 100.0

[screws_tilt_adjust]

screw1: 22,83

screw1_name: front left

screw2: 222,83

screw2_name: front right

screw3: 22,283

screw3_name: back left

screw4: 222,283

screw4_name: back right

speed: 100.0

screw_thread: CW-M5

[bed_mesh]

speed: 800

mesh_min: 30,30

mesh_max: 270,270

probe_count: 5,5

mesh_pps: 2,2

algorithm: bicubic

bicubic_tension: 0.2

move_check_distance: 3.0

split_delta_z: .010

fade_start: 1.0

fade_end: 5.0

########################################

# EXP1 / EXP2 (display) pins

########################################

[board_pins]

aliases:

# EXP1 header

EXP1_1=PC5, EXP1_3=PB1, EXP1_5=PE10, EXP1_7=PE12, EXP1_9=<GND>,

EXP1_2=PB0, EXP1_4=PE9, EXP1_6=PE11, EXP1_8=PE13, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PA6, EXP2_3=PE7, EXP2_5=PB2, EXP2_7=PC4, EXP2_9=<GND>,

EXP2_2=PA5, EXP2_4=PA4, EXP2_6=PA7, EXP2_8=<RST>, EXP2_10=<NC>

# See the sample-lcd.cfg file for definitions of common LCD displays.

[gcode_macro update_git]

gcode:

RUN_SHELL_COMMAND CMD=update_git_script

[gcode_shell_command update_git_script]

command: bash /home/wilsonm/printer_1_data/klipper-backup/script.sh

timeout: 90.0

verbose: True

Creality CR6 SE

Creality CR6 SE landing page.

Voron 2.4 Pro+

Voron 2.4 landing page.

Zero G Mercury One.1

Mercury One.1 landing page.

Mercury One.1 with a BTT Manta M8P

[include shell_command.cfg]

[include mainsail.cfg]

# host MCU service is preinstalled and ready to use with:

[mcu CB1]

serial: /tmp/klipper_host_mcu

# This file contains common pin mappings for the BIGTREETECH Manta M8P

# To use this config, the firmware should be compiled for the

# STM32G0B1 with a "8KiB bootloader" "8 MHz crystal"

# and "USB (on PA11/PA12)" or "CAN bus (on PD12/PD13)".

# https://github.com/Klipper3d/klipper/blob/master/config/generic-bigtreetech-manta-m8p-v1.1.cfg

# See docs/Config_Reference.md for a description of parameters.

[mcu]

#@serial: /dev/serial/by-id/usb-Klipper_stm32g0b1xx_3C001B000B504B4633373520-if00

canbus_uuid=5b426f4e5253

[mcu HermitCrab]

#serial: /dev/serial/by-id/usb-Klipper_stm32f072xb_28002C000757434331363920-if00

canbus_uuid=00ee6e545867

[printer]

kinematics: corexy

max_velocity: 300

max_accel: 4000 #Max 4000

max_z_velocity: 15 #Max 15 for 12V TMC Drivers, can increase for 24V

max_z_accel: 350

square_corner_velocity: 5.0

[stepper_x] # B M1

step_pin: PE2

dir_pin: !PB4

enable_pin: !PC11

rotation_distance: 40

microsteps: 16

full_steps_per_rotation: 200 #set to 200 for 1.8 degree stepper

endstop_pin: ^PF3

position_endstop: 357

position_max: 377

homing_speed: 50

homing_retract_dist: 10

[tmc5160 stepper_x]

cs_pin: PC10

#spi_bus: spi1

interpolate: False

run_current: .7

#diag1_pin: ^!PF3

sense_resistor: 0.110

#driver_SGTHRS: 125

driver_SGT: 0

stealthchop_threshold: 0

spi_software_sclk_pin: PA5

spi_software_mosi_pin: PA7

spi_software_miso_pin: PA6

[stepper_y] # A M2

step_pin: PF12

dir_pin: !PF11

enable_pin: !PB3

rotation_distance: 40

microsteps: 16

full_steps_per_rotation: 200 #set to 200 for 1.8 degree stepper

endstop_pin: ^PF4

position_endstop: 365

position_max: 370

homing_speed: 50

homing_retract_dist: 10

[tmc5160 stepper_y]

cs_pin: PF13

#spi_bus: spi1

interpolate: False

run_current: .7

#hold_current: 1.0

#diag1_pin: ^!PF4

sense_resistor: 0.110

#driver_SGTHRS: 125

driver_SGT: 2

stealthchop_threshold: 0

spi_software_sclk_pin: PA5

spi_software_mosi_pin: PA7

spi_software_miso_pin: PA6

[stepper_z] # M3 Left

step_pin: PD7

dir_pin: !PD6

enable_pin: !PF10

microsteps: 16

rotation_distance: 2

full_steps_per_rotation: 200 #set to 200 for 1.8 degree stepper

endstop_pin: probe:z_virtual_endstop

position_max: 350

position_min: -50

homing_speed: 8.0

second_homing_speed: 3

[tmc2209 stepper_z]

uart_pin: PF9

##diag_pin: PF5

run_current: 0.7

sense_resistor: 0.110

stealthchop_threshold: 0

[stepper_z1] # M4 Center

step_pin: PD3

dir_pin: !PD2

enable_pin: !PD5

microsteps: 16

rotation_distance: 2

full_steps_per_rotation: 200 #set to 200 for 1.8 degree stepper

[tmc2209 stepper_z1]

uart_pin: PD4

##diag_pin: PC0

run_current: 0.7

sense_resistor: 0.110

interpolate: False

stealthchop_threshold: 0

[stepper_z2] # M6 Right

step_pin: PA10

dir_pin: !PA14

enable_pin: !PA15

microsteps: 16

rotation_distance: 2

full_steps_per_rotation: 200 #set to 200 for 1.8 degree stepper

[tmc2209 stepper_z2]

uart_pin: PF8

run_current: 0.7

sense_resistor: 0.110

interpolate: False

stealthchop_threshold: 0

[extruder]

step_pin: HermitCrab: PA6

dir_pin: !HermitCrab: PA7

enable_pin: !HermitCrab: PA5

microsteps: 16

rotation_distance: 24.235

gear_ratio: 7:1

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: HermitCrab: PA2

sensor_type: EPCOS 100K B57560G104F

sensor_pin: HermitCrab: PA1

#control: pid

#pid_Kp: 21.527

#pid_Ki: 1.063

#pid_Kd: 108.982

min_temp: 0

max_temp: 250

max_extrude_cross_section: 4

pressure_advance: 0.05

[tmc2209 extruder]

uart_pin: HermitCrab: PB0

run_current: 0.650

sense_resistor: 0.110

interpolate: false

stealthchop_threshold: 0

[fan]

pin: HermitCrab: PA4

[heater_fan hotend_fan]

pin: HermitCrab: PA3

heater: extruder

heater_temp: 50.0

#####################################################################

# Bed Heater

#####################################################################

[heater_bed]

## SSR Pin - BED_OUT

heater_pin: PB5

sensor_type: ATC Semitec 104GT-2

sensor_pin: PA0

## Adjust Max Power so your heater doesn't warp your bed

max_power: 0.7

min_temp: 0

max_temp: 120

#control: pid

#pid_kp: 58.437

#pid_ki: 2.347

#pid_kd: 363.769

[board_pins]

aliases:

# EXP1 header

EXP1_1=PE9, EXP1_2=PE10,

EXP1_3=PE11, EXP1_4=PE12,

EXP1_5=PE13, EXP1_6=PE14, # Slot in the socket on this side

EXP1_7=PE15, EXP1_8=PB10,

EXP1_9=<GND>, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PB14, EXP2_2=PB13,

EXP2_3=PF7, EXP2_4=PB12,

EXP2_5=PE7, EXP2_6=PB11, # Slot in the socket on this side

EXP2_7=PE8, EXP2_8=<RST>,

EXP2_9=<GND>, EXP2_10=<NC>

# See the sample-lcd.cfg file for definitions of common LCD displays.

#####################################################################

# Probe

#####################################################################

[safe_z_home]

home_xy_position: 188,185

speed: 150

z_hop: 10 # Move up 10mm

z_hop_speed: 5

[bltouch]

sensor_pin: ^HermitCrab:PB2

control_pin: HermitCrab:PB1

x_offset: -31.8

y_offset: -40.5

#z_offset: 4 # Uncomment if starting fresh; Distance should be enough to keep the z-offset positive.

speed: 5.0

pin_move_time: 0.7

lift_speed: 8

pin_up_touch_mode_reports_triggered: True

probe_with_touch_mode: True

samples: 2

samples_result: median

sample_retract_dist: 6.0

samples_tolerance: 0.05

samples_tolerance_retries: 3

[bed_mesh]

speed: 300

mesh_min: 30,30

mesh_max: 345,329

probe_count: 5,5

mesh_pps: 2,2

algorithm: bicubic

bicubic_tension: 0.2

move_check_distance: 3.0

split_delta_z: .010

fade_start: 1.0

fade_end: 10.0

[screws_tilt_adjust]

screw1: 360,13.5

screw1_name: front_left

screw2: 360,363

screw2_name: front_right

screw3: 185,10

screw3_name: back_middle

# Additional bed leveling screws. At least two screws must be

# defined.

speed: 50

horizontal_move_z: 5

screw_thread: CW-M3

[bed_screws]

screw1: 360,13.5

screw2: 360,363

screw3: 185,10

[z_tilt]

z_positions:

10,13.5

185,350

355,13.5

points:

0,55

155,365

325,55

speed: 200

horizontal_move_z: 15

retries: 10

retry_tolerance: 0.03 #0.0075

#####################################################################

# PInput Shaping

#####################################################################

[adxl345]

cs_pin: HermitCrab: PB12

spi_bus: spi2

axes_map: y,z,-x

[resonance_tester]

accel_chip: adxl345

probe_points:

188,185, 20 # middle of bed as an example

[input_shaper]

shaper_freq_x: 43.0

shaper_type_x: 2hump_ei

shaper_freq_y: 52.6

shaper_type_y: 2hump_ei

#####################################################################

# Macros

#####################################################################

# All customizations are documented in globals.cfg. Just copy a variable from

# there into the section below, and change the value to meet your needs.

[gcode_macro _km_options]

# These are examples of some likely customizations:

# Any sheets in the below list will be available with a configurable offset.

#variable_bed_surfaces: ['smooth_1','texture_1']

# Length (in mm) of filament to load (bowden tubes will be longer).

variable_load_length: 50.0

# Hide the Octoprint LCD menu since I don't use it.

#variable_menu_show_octoprint: False

# Customize the filament menus (up to 10 entries).

#variable_menu_temperature: [

# {'name' : 'PLA', 'extruder' : 200.0, 'bed' : 60.0},

# {'name' : 'PETG', 'extruder' : 230.0, 'bed' : 85.0},

# {'name' : 'ABS', 'extruder' : 245.0, 'bed' : 110.0, 'chamber' : 60}]

# Length of filament (in millimeters) to purge at print start.

variable_start_purge_length: 30 # This value works for most setups.

gcode: # This line is required by Klipper.

# Any code you put here will run at klipper startup, after the initialization

# for these macros. For example, you could uncomment the following line to

# automatically adjust your bed surface offsets to account for any changes made

# to your Z endstop or probe offset.

# ADJUST_SURFACE_OFFSETS

variable_park_x: 10.0

# Y position to park toolhead (set "max" or "min" to infer from stepper config).

variable_park_y: 350.0

# This line includes all the standard macros.

[include klipper-macros/*.cfg]

# Uncomment to include features that require specific hardware support.

# LCD menu support for features like bed surface selection and pause next layer.

#[include klipper-macros/optional/lcd_menus.cfg]

# Optimized bed leveling

[include klipper-macros/optional/bed_mesh.cfg]

# The sections below here are required for the macros to work. If your config

# already has some of these sections you should merge the duplicates into one

# (or if they are identical just remove one of them).

[idle_timeout]

gcode:

_KM_IDLE_TIMEOUT # This line must be in your idle_timeout section.

[pause_resume]

[respond]

[save_variables]

filename: ~/printer_data/config/variables.cfg # UPDATE THIS FOR YOUR PATH!!!

[virtual_sdcard]

path: ~/printer_data/gcodes # UPDATE THIS FOR YOUR PATH!!!

on_error_gcode: CANCEL_PRINT

[display_status]

[exclude_object]

[gcode_macro update_git]

gcode:

RUN_SHELL_COMMAND CMD=update_git_script

[gcode_shell_command update_git_script]

command: bash -c "bash $HOME/klipper-backup/script.sh"

timeout: 90.0

verbose: True

3D Printer and 3D Printing Accessory Reviews

Over the past couple of years, I have had an opportunity to try many different 3D Printers and 3D Printing parts/accessories. In this section, I will document the various products I have either tested or used.

Level Up Your 3D Printer! FIXDRY DOUBLE-NT1 Filament Dryer Box Review & Demonstration

red of battling wet filament and failed 3D prints? Struggling to keep your prints crisp and free of warping?

In this video, we take action! We unbox and put the FIXDRY DOUBLE-NT1 Filament Dryer to the test. See for yourself how this 2-spool dryer can transform your printing experience.

We’ll show you exactly how it works, test its drying capabilities, and reveal if the FIXDRY DOUBLE-NT1 is the key to unlocking perfect prints. Don’t waste another minute on failed projects - watch now and take control of your filament!

Plus: Stick around for a special bonus at the end - we’ll share our top tips for getting the most out of your filament dryer!

FIXDRY 3D Filament 2 Spools Compatible Dryerbox DOUBLE-NT1: https://bit.ly/3vSfOOa

Amazon Link: https://amzn.to/4apTZEN

M3DP Tutorials

These are the tutorials I have created over the years. I have tried to create playlists on YouTube. My focus is 3D printing slicers, Klipper, and Marlin setups. I also do a lot of videos on repairing 3D printers. I am always looking for new ideas. Don’t hesitate to reach out with some suggestions.

Orca Slicer Tutorials

Orca Slicer landing page.

According to Prusa3D, Max Volumetric Speed is defined as:

The Maximum volumetric speed setting (MVS) is one of the most powerful features in PrusaSlicer. The MVS setting essentially creates a manager for the maximum amount of filament that the slicer will attempt to push through your 3D printer’s hotend.

Dial in Your Prints: OrcaSlicer Max Flow Rate Calibration Test

Stop printing with gaps and blobs! Master your flow rate with OrcaSlicer’s built-in Max Flow Rate Calibration Test.

This beginner-friendly tutorial will guide you step-by-step through the entire calibration process. Learn how to:

Say goodbye to under-extrusion and hello to smooth surfaces and sharp details! This video is perfect for anyone who wants to take their 3D printing to the next level with OrcaSlicer.

Calibration Spreadsheet: https://docs.google.com/spreadsheets/d/1LlSHsa86RuT_btswmDsmQp0LrTJ9U0HJcRhorsqz1ug/edit?usp=sharing

References:

#3dprinting #klipper #3dprinter #orcaslicer

Ultimake Cura Tutorials and References

Cura GitHub - Cura Logo

Photo: Various

Cura Tutorials Landing Page.

Downloading and Installing Cura

*.exe for Windows, *.dmg for Mac).(1) UltiMaker Cura - UltiMaker. https://ultimaker.com/software/ultimaker-cura/. (2) Install Ultimaker™ Cura on Ubuntu using the Snap Store - Snapcraft. https://snapcraft.io/install/cura-slicer/ubuntu. (3) UltiMaker Cura installation. https://support.ultimaker.com/s/article/1667410778218. (4) How to Use Ultimaker Cura to Prepare Designs for 3D Printing. https://www.tomshardware.com/how-to/use-ultimaker-cura-to-prepare-designs-for-3d-printing. (5) Cura. https://ultimaker.com/software/ultimaker-cura.

As I plan projects, I wanted a place where I could gather my thoughts and plans. I also want to start keeping project journals.

It usually takes me a while to work on my various projects. I store references all over the place. I am hoping that this could be a place for me to gather everything. As I work in a project, I would like to be able to document the process.

I have alot of projects planned for Minimal 3DP. I look forward to getting to work and sharing.

Voron 2.4 R2 Project log and References

Voron 2.4 R2 landing page.

Build references and links for the Voron 2.4 R2 Pro+ FormBot kit. I needed a centralized location for all the reference material I need to build the 3D printer.

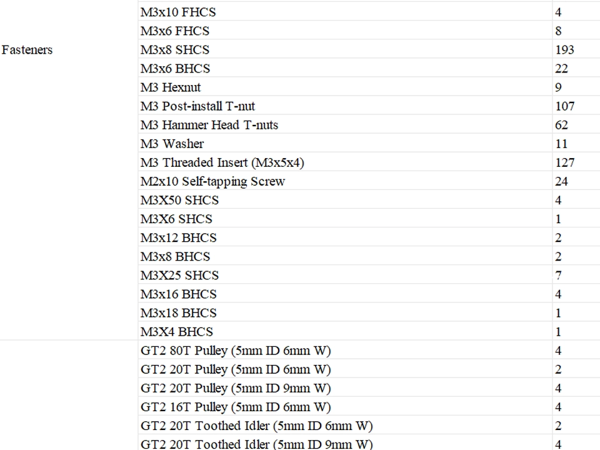

Parts List for the Voron 2.4 R2 Pro+ FormBot kit. I will show the parts list from FrormBot but at the end of the page I will include my cross-checks.

FormBot Parts List

FormBot Parts List

Photo: Various Sources

In this section, I will be building the frame of my Voron 2.4 R2 Kit

References and Links

The Voron assembly manual starts with the building of the frame. I will start from this point.

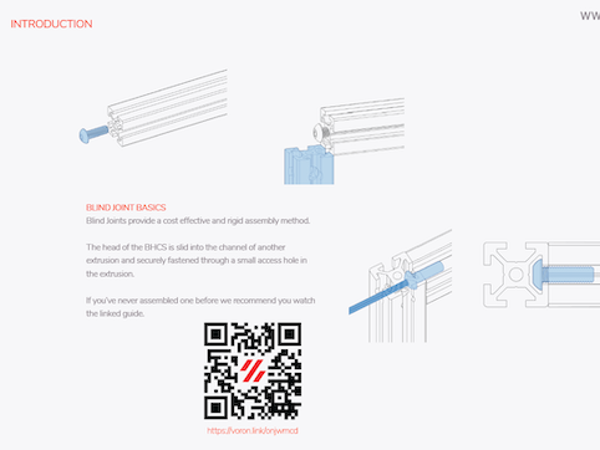

Voron Build Guide - Blind Joints

Photo: Various

Using the blind joints. The Frame is assembled.

Assembled Frame

Photo: Various

Belt Driven Ender 3 Project Log and References

Belt Driven Ender 3 landing page.

vzBot Project log and References

vzBot landing page.